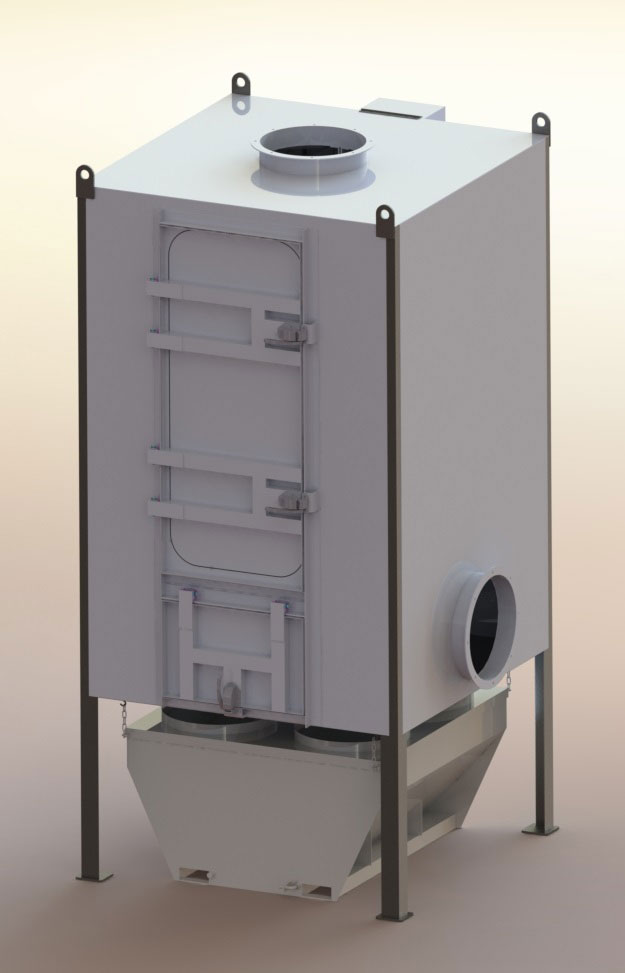

All of our B style shaker units are fabricated using heavy gauge steel and painted inside and out for years of continued use. They feature a unique cyclone design built into the inlet which others do not have. This design attributes to the long life of the filters which our customers enjoy versus changing filters every few years or less. The air comes into the unit at the NFPA 4500 ft/min and strikes our internal splitter which imparts a cyclonic spin to the air-stream. This in-turn, separates the dust and air before it travels upwards to the filters at a rate of about 85% efficiency, knocking our the bulk of dust before the filters. Only fine dust really enters the filters and some of the larger shavings.

Therefore the B unit is available with 5" diameter filter bags if most of the work is fine dust and also in 8" diameter filter bags if it is a mixed dust.

The operator simply turns the machine on in the morning and works for 4-5 hours, then shuts the machine down. Once the fan stops, the shaker motor starts and shakes the dust from the bags free, so that it falls into the dust storage drums, bags or bin below the unit.

This process takes approx. 15 minutes during a lunch break. Once the shaker stops, the unit is clean and is ready for another 4-5 hours of filtering. This simple process can go on repeatedly for many years without having to perform any maintenance to the units or change filters. We do recommend following a simple check after a given time frame to ensure everything is working correctly with the machine.

The B style unit can be oriented in 7 different arrangements depending on the individual need and can be outfitted with features to operate inside our outside and meet all current regulations.

The unit ships ready to be electrically wired and bolted to the ground on a concrete floor or outside pad.

The B unit is the lowest cost unit to own on the market.