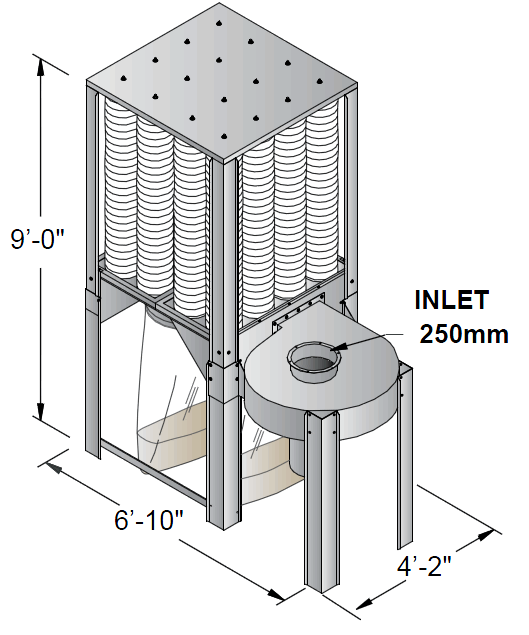

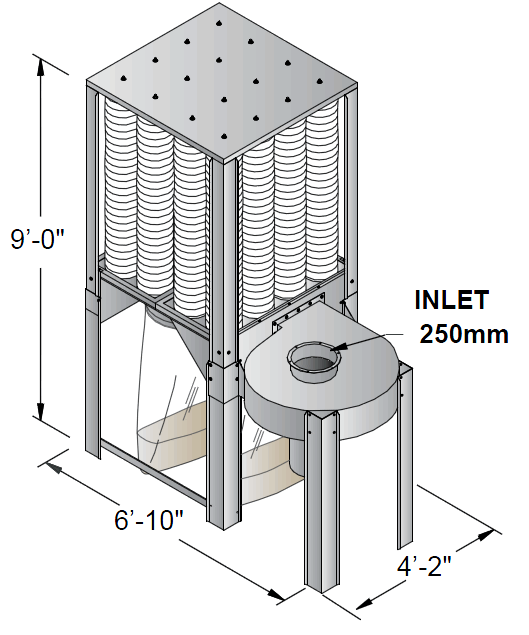

S-500

SKU : S-500

Product Details

The S-Series S-500 is sized for 3,000 CFM and is suitable for collection of many different types of dust including

wood, paper and plastic. Applications: High Speed Routing • Sawing • Cutting • Single 'Cell' Manufacturing • After-Filters

Benefits • Single or three phase • Easy installation • Small footprint

How it Works

...during normal operation

- During normal operation, the dust laden air from the plant travels down the supply duct

- The dirty air then enters the COMBIFAB material handling fan

- The dust then enters the hopper section of the filter

- As air slows down within the hopper, the heavier dust particles fall down into the inside of the collection bags

- The remaining dust then travels up into the inside of the filter bags

- The air, which originated from the plant, is now clean and passes through the filter bag into the surrounding atmosphere

...while cleaning

- The S Series may only clean "off-line", when the COMBIFAB fan has stopped rotating

- The S Series is cleaned by applying physical force to the outside of the filter bag which, in effect, shakes them

- The dust cake, which hangs on the inside of the filter bag, falls into the hopper section and then into the collection bags below

Basic Model Features

- Qty (1) 5 HP, 1750 RPM, TEFC motor

- Qty (16) Beane material filter bags

- Qty (2) plastic waste collection bag

- Qty (2) clamps for easy removal of waste bags

- 162 Sq Ft of filter media

- Easy installation

- Quiet operation

- Two waste discharge points

Options

- Available in 3-phase and 1-phase

- Motor Starters

- Two 42 gallon drums

- Inlet adapter to Nederman Quick-Fit, or raw edge

- Complete Nederman Quick-Fit Duct packages

- Available without fan as afterfilter

CFM Range

- 8.0" Wg

- 7.5" Wg

- 5.0" Wg

- 1500 CFM

- 2000 CFM

- 3000 CFM

- Shipping Weight: 600 lbs.

- Shipping Dimensions: 48" x 96" x 67"

- EASY AS 1-2-3

- Collector up and running in less than 1 hour

The Superbag

- A filter is only as good as the filter bags it uses and this is the component that provides the filtering while allowing clean air to pass through with the least possible resistance. Therefore, the lowest possible consumption of energy is realized, even after several thousand hours of operation. Nederman patented filter bag, is fitted as the standard in all S-Series bag filters.

- High-End Filter Bag

- Same material used in larger dust collectors

- Superior performance with an economical design

- Long life for reduced maintenance

- No cage to wear holes in the bags.

- Patented Weaving Process

- Material stretches to improve cleaning/dust release

- Seamless bag body: maximizes usable filter area and improves efficiency

- Low static resistance for maximum airflow

- High filter efficiency for indoor use

- Interwove anti-static carbon fiber wire reduces static fire risk.

- Antistatic

- Superbag's interwoven carbon fiber wire provides higher anti-static properties than traditional filter bags, both on the surface and inside. This reduces the risk of fire and explosion as fine particles are removed.

Dump Bin for the S-Series

-

Dimensions :

- Overall 33.0" wide x 72" long x 36.5" high

- Inside 29.0" wide x 67.5" long x 27.5" high

- Shipping Weight: 550 lbs

- Shipping Deminsions: 36" x 76" x 43"

-

Volume :

230 gallon

[ 70% increased capacity over a (3) barrel outlet ] barrels are 45 gallon each

-

Construction :

14 ga galvanized steel